Containers/packaging

At J-Oil Mills, we develop containers and packaging with the keywords "environmental friendliness" and "usability/ease of use."

In conjunction with product development, we strive to develop containers that are easy to use and address the concerns of our customers, while also being considerate of the global environment.

In addition, in light of the current situation in which the problem of plastic waste is becoming more serious, in 2019 we launched the Packaging Committee as an internal cross-sectional organization and established the "Guidelines for Containers and Packaging."

We will continue to work together across the company to strengthen the development of containers and packaging that address social issues.

Company-wide development of containers and packaging

The Packaging Subcommittee, which is a company-wide organization centered on the packaging materials procurement and packaging technology departments, and which also includes the research and development department, quality assurance department (customer service center), business department, and production and logistics department, formulates the Container and Packaging Guidelines.

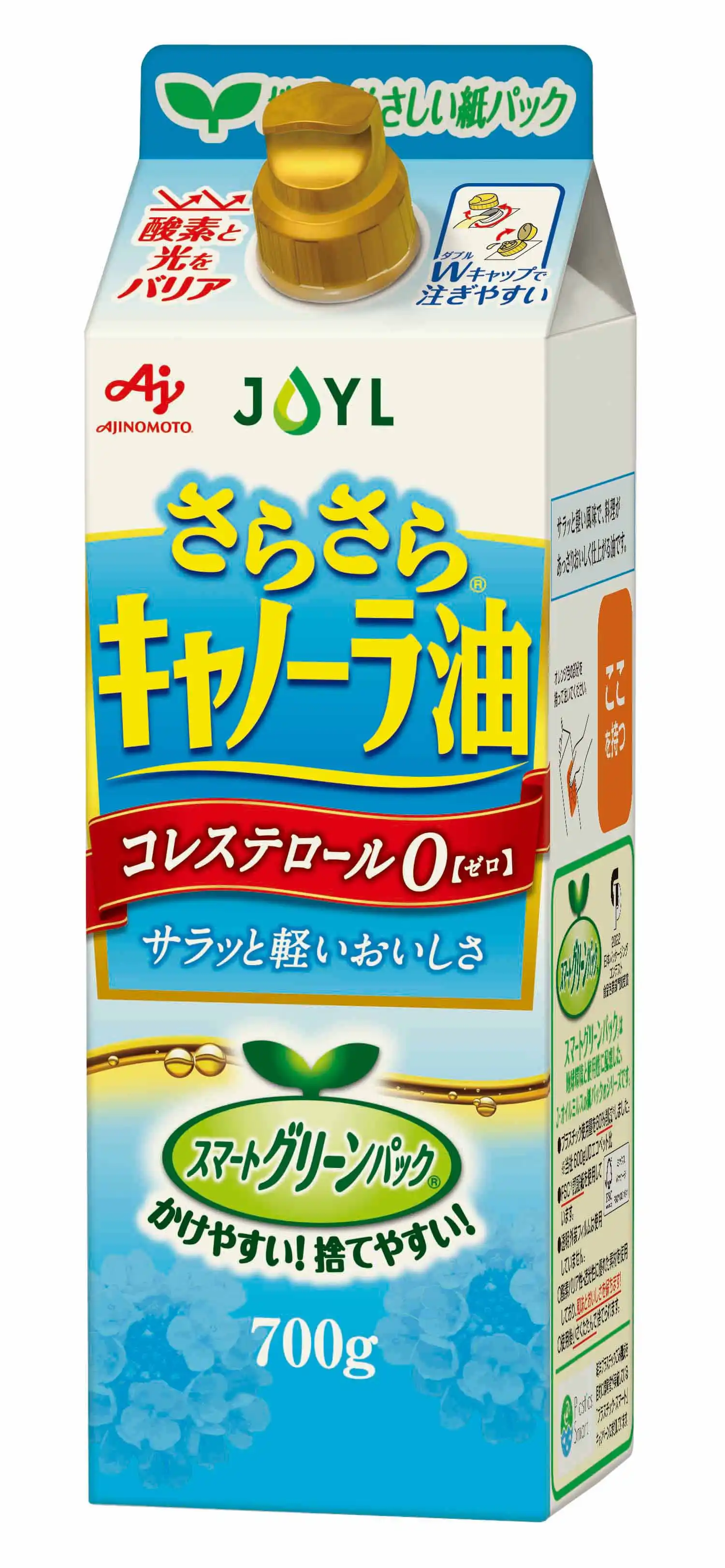

The subcommittee's proposal led to the start of development of the "Smart Green Pack® (J-Oil Mills' paper pack series that takes into consideration the global environment and ease of use)." This is an original J-Oil Mills paper pack developed specifically for edible oils.

Conventional caps for paper cartons are prone to dripping oil, but by processing them into our unique shape, we have developed a cap that is less prone to dripping oil even when pouring small amounts, making it easy to pour. Furthermore, by making the cap a double (W) structure for both large and small amounts, you can choose the amount you want to pour depending on the purpose.

The sides of the paper carton are embossed with a unique shape to make them less slippery and easier to pour. In addition, by laminating an inorganic vapor deposition film with excellent oxygen barrier properties, this, together with the light-blocking properties of the paper, prevents the oxidation of oil, thereby extending the shelf life.

Compared to conventional plastic containers, the new containers reduce the amount of plastic used andCO2emissions (*), and we have worked to design environmentally friendly containers by using paper that is certified to be harvested, transported, and processed in properly managed forests, as its main raw material.

(*) Compared to conventional plastic containers of the same volume, this reduces plastic usage by more than 60% and reduces CO2 emissions (carbon dioxide emissions from the manufacturing to disposal of the container) per 1 kg of oil in the paper carton by more than 26% (according to our calculations).

Collaboration with Ajinomoto Group companies

We jointly procure container and packaging materials with Ajinomoto Co., Inc., and cooperate with the Ajinomoto Group to accept and consider new proposals and engage in joint development with suppliers.

By consolidating this effort as a large-scale initiative within the Ajinomoto Group, we are able to work with suppliers to resolve issues more quickly.

Development Goals

ECO |

U.D. |

Environmental ResponseImproved and lightweight packaging, disposal measures (volume reduction, sorting) |

UsabilityEasy to hold, easy to pour, easy to understand |

|

Based on the premise of ensuring safety, hygiene and quality, |

Accessible to as many people as possible Realize the provision of products (services). |

Smart Green Pack® Series

The Smart Green Pack® series, which went on sale in August 2021, uses paper cartons as containers, which is rare for oil products, and pursues packaging functionality and environmental friendliness.

Food packaging category award

Japan Federation of Printing Industries Chairman's Award

*Both awards will be awarded in 2022, and the packaging is the current image.

Double cap with drip prevention function

(Patent pending, design registered)

The "Smart Green Pack®"series' unique "anti-drip cap" addresses the issue of dripping from the spout, which was previously an issue with paper containers for edible oil, by curling the tip of the spout. In addition, the double cap, which allows you to change the amount of pouring depending on the application, has a hinge structure that allows it to be opened and closed with one hand, further improving usability.

Improvement and rationalization department

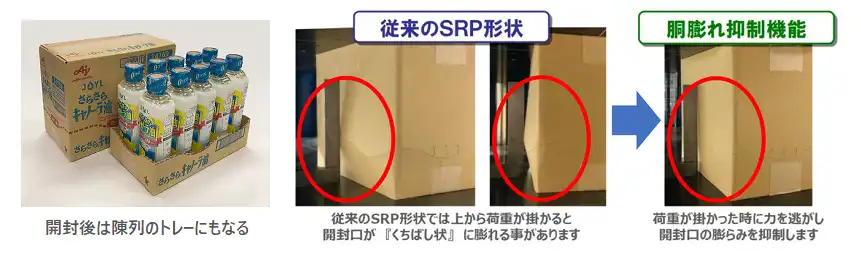

SRP Corrugated Board

In order to reduce the burden on customers who put out and display products and to shorten the time it takes to display products, 「

「![]() The outer PET outer box for the 350g"Sarasara® Canola Oil" was converted to SRP. In addition, to address the risk of bulging or breaking of the perforations due to the stress placed on the opening part, a guide shape was developed and introduced to distribute the load applied during loading. This reduced bulging of the cardboard and improved distribution issues.

The outer PET outer box for the 350g"Sarasara® Canola Oil" was converted to SRP. In addition, to address the risk of bulging or breaking of the perforations due to the stress placed on the opening part, a guide shape was developed and introduced to distribute the load applied during loading. This reduced bulging of the cardboard and improved distribution issues.

Transportation packaging category award

Easy-to-open display case

To make it easier for customers to work in the store,![]() 「

「![]() Olive oil,

Olive oil,![]() 「

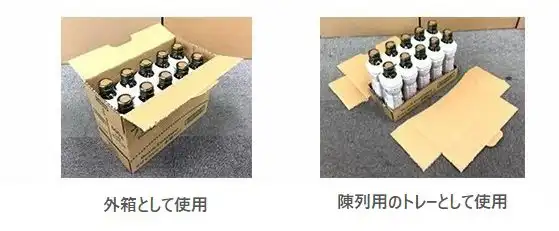

「![]() Olive Oil Extra Virgin 600g UD PET bottles have been converted to SRP, and a 2-way easy-open display case has been adopted, which can be used as both a display tray and a box. *Patent pending

Olive Oil Extra Virgin 600g UD PET bottles have been converted to SRP, and a 2-way easy-open display case has been adopted, which can be used as both a display tray and a box. *Patent pending

Fresh-keeping pouch (UD eco pouch)

This environmentally friendly package uses biomass materials * not only for the gas barrier layer of the pouch, but also for the sealant *.

Easy to open even with wet hands

A special varnish that has an anti-slip effect is used on the opening.

By using SPR * cardboard, products can be displayed in boxes, reducing the workload at the storefront.

Accessible Design Packaging Award

*Sealant: A material that is heat-bonded to form a bag shape.

*Biomass materials: Renewable organic resources.

*SRP: Shelf Ready Packaging. Packaging that can be opened without the use of a cutter or other tool and can be displayed in stores as is.

160g glass bottle

The glass bottles have been made lighter than before, and by revising the shape of the bottles, collisions between bottles have been reduced, making dividers in the outer box unnecessary.

Additionally, by making the outer box more compact, we were able to increase loading efficiency by 30%.

Food packaging category award

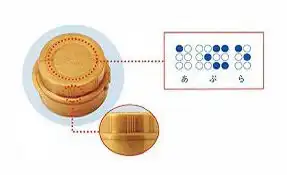

UD Cap Series

The UD caps that were introduced on some products in 2004 have now been expanded to all household containers.

The lid has been given Braille treatment and has been improved to prevent oil dripping, making it easier to handle.

Food packaging category award

400gUD Eco Pouch Biomass Specification

PET made from sugarcane molasses is coated with a vapor-deposited* barrier and used to make pouches.

New Creation Category

Food packaging category award

* Vapor deposition: A surface treatment in which inorganic substances such as ceramics are evaporated and attached to the surface of a material.

340g glass bottle

While maintaining the bottle's design, it is also designed to be easy to hold.

The dividers in the outer box have been reduced and surrounding packaging materials have been streamlined.

Nemoto Mio Award

Food packaging category award

Bag-in-box (BIB) Universal Design

"Here's the handle ®", "Soko handle ®"

To improve work efficiency at customers' stores, we have adopted packaging with a handle that can be smoothly formed to fit the flap* of the commercial BIB* packaging.

The soft PP band makes it easy to hold, and the material used for the tape holding the outer box together has been revised to make it easier to disassemble.

Accessible Design Award

*BIB (Bag in Box): A commercial liquid container made of cardboard with an inner plastic bag.

*Flap: A term that refers to the covers on the top and bottom of a cardboard box.

400gUD KOKO Pouch (Standing Pouch for Edible Oil)

The container has a subtle curve called the "easy-to-hold curve" and a small uneven surface called the "grainy stopper" to make it easy to hold. By rolling it up, it becomes 1/10 of its original size, which has resulted in a significant reduction in waste.

600gUD COPPER

The amount of bottle resin used has been reduced by 20%, and plant-based materials have been used for the cap seal.

To ensure ease of holding even when the contents are low, the bottle is flattened, the bottom part is shaped, and a drop prevention stopper (dent: finger spot) is provided. The spout is also designed to make it easy to adjust the amount of oil.

Tactile Identification Award

1000g Copac

The paper carton used is the first edible oil container to be Eco Mark certified. The outer box is made of recycled paper and is designed to be easily disassembled. The inner bag can be folded up small and thrown away. The handle of the paper carton is indented to make it easier to hold, and the embossed finish makes it less slippery. Environmentally friendly soybean ink is used for printing.

Japan Star Award

Minister of Economy, Trade and Industry Award

Improvement and rationalization department

Renewal Category Award

Excellent Machinery and Materials Award

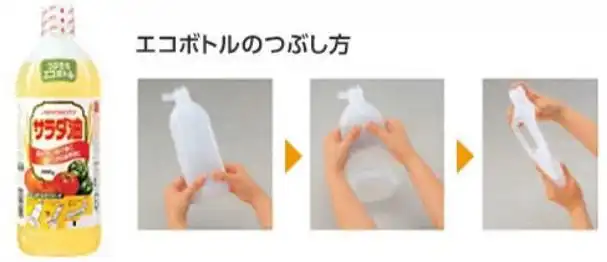

Crushable Eco Bottle 1000g

The bottle is lightweight and designed to be easily crushed and thrown away.

Japan Star Award

Japan Marketing Association Chairman's Award

Fresh-keeping bottle for gifts

We were the first in the industry to introduce the "barrier bottle," which uses ceramic deposition technology to create an extremely hard film that protects the contents from oxygen.

Japan Printing Industry Federation Chairman's Award