Resource Circulation

Waste reduction and recycling

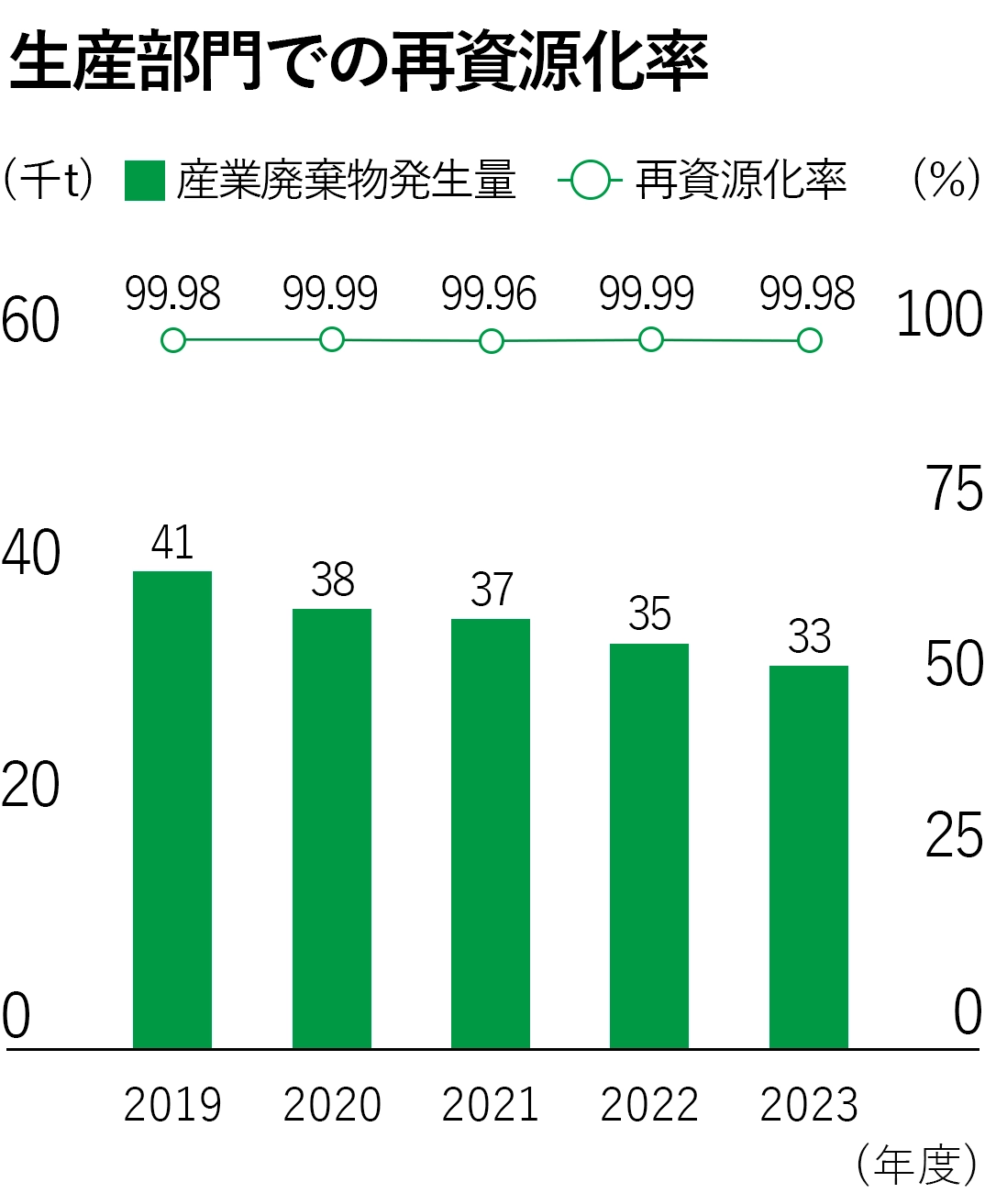

J-Oil Mills promotes waste reduction and recycling, and achieves zero emissions* every year. In fiscal 2023, we will continue to promote the conversion of waste into valuable materials, and maintain and maintain our target recycling rate of 99.9% or more in the production division. We will continue to strive to reduce the amount of energy, raw materials, water, and other inputs, and work to reduce and recycle pollutants and waste emissions. In addition, we will strive to reduce the amount of plastic derived from fossil fuels, and non-production divisions will also hold e-learning and environmental seminars on waste, and the entire company will work to maximize resource utilization efficiency.

*At our company, we define zero emissions as not incinerating or disposing of industrial waste generated at our factories and offices in landfills (recycling rate of 99.9% or more).

Water Resource Conservation

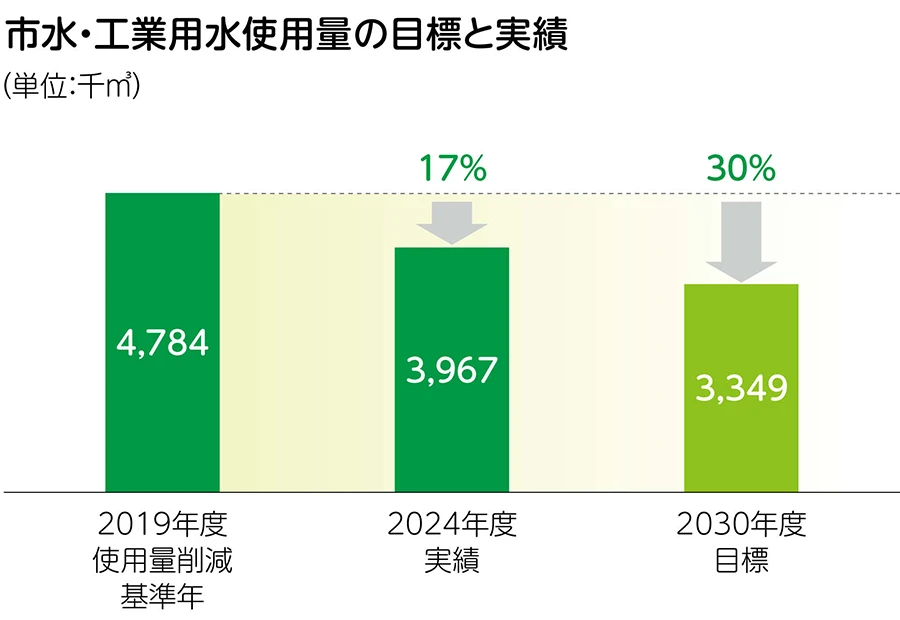

水は、原料作物の栽培や、製造⼯程など、サプライチェーンにおけるあらゆる場面で使用され、当社の事業活動に⽋かすことのできない⼤切な資源です。当社の⼯場は蒸気や冷却⽤媒体として多くの⽔を使⽤しています。当社では、市水・工業用水使用量を2030年度までに2019年度比で30%削減する目標を掲げ、効率的な⽔利⽤、再利⽤を促進し、取⽔量削減に努めています。2024年度の国内全工場の水使用量は3,967千m3と、2019年比で17%の削減となりました。

また、2021年度より、取締役が委員長を務めるサステナビリティ委員会傘下の「環境分科会」において、CTOが最高責任者となり国内拠点の水リスクの検討・分析を開始しています。今後は、食品企業にとって重要な水リスクを把握し、リスクの排除に努めるとともに、環境保全と事業継続のため水資源に対するさらなる取り組みを進めていきます。

Appropriate management of chemical substances

We strive to properly manage the chemical substances we handle in accordance with laws and regulations such as the Act on Reporting, etc. of Releases to the Environment of Chemical Substances and Promotion of Improvements in Their Management (PRTR Act), and we also properly manage other chemical substances.

Regarding PCB waste, we report the storage of PCB waste and dispose of it in a planned manner in accordance with the Act on Special Measures Concerning Promotion of Proper Disposal of Polychlorinated Biphenyl Waste (PCB Special Measures Act).

Guidelines for containers and packaging

| Guidelines for containers and packaging |

|---|

| We will seek out and adopt new technologies for recycling containers and packaging materials such as bottles, cans, and paper. |

| We strive to develop environmentally friendly products, such as by using product designs that reduce the amount of plastic containers and packaging used, and by using plant-based and easily recyclable materials. |

| We will promote the use of FSC-certified paper. |

| We will promote procurement of materials from companies that take ESG into consideration. |

| We strive to develop containers and packaging that can accommodate a diverse range of users. |

| We consider the entire supply chain and address transportation efficiency and labor shortages. |

Tackling the plastic problem

In May 2022, we established a goal of achieving "zero plastic waste" for fiscal 2030.

In 2021, we set a goal of reducing our plastic waste volume by 25% by 2030 compared to fiscal 2000 levels, and have been implementing various initiatives to achieve this goal. However, with the enforcement of the Act on Promotion of Resource Recycling Related to Plastics, we believe that we need to work even harder than before to reduce plastic waste, which causes marine environmental pollution and climate change, and have therefore revised our target upward.

To achieve this goal, we will work to develop and sell environmentally friendly products by expanding our "Smart Green Pack®" series of environmentally friendly products that use paper cartons, adopting biomass resins, reusing waste plastics and using recycled resins, and promoting the development of recycling technologies through collaboration between companies. We will continue to work to reduce the use and waste of plastic in stages and reduce the burden on the environment.

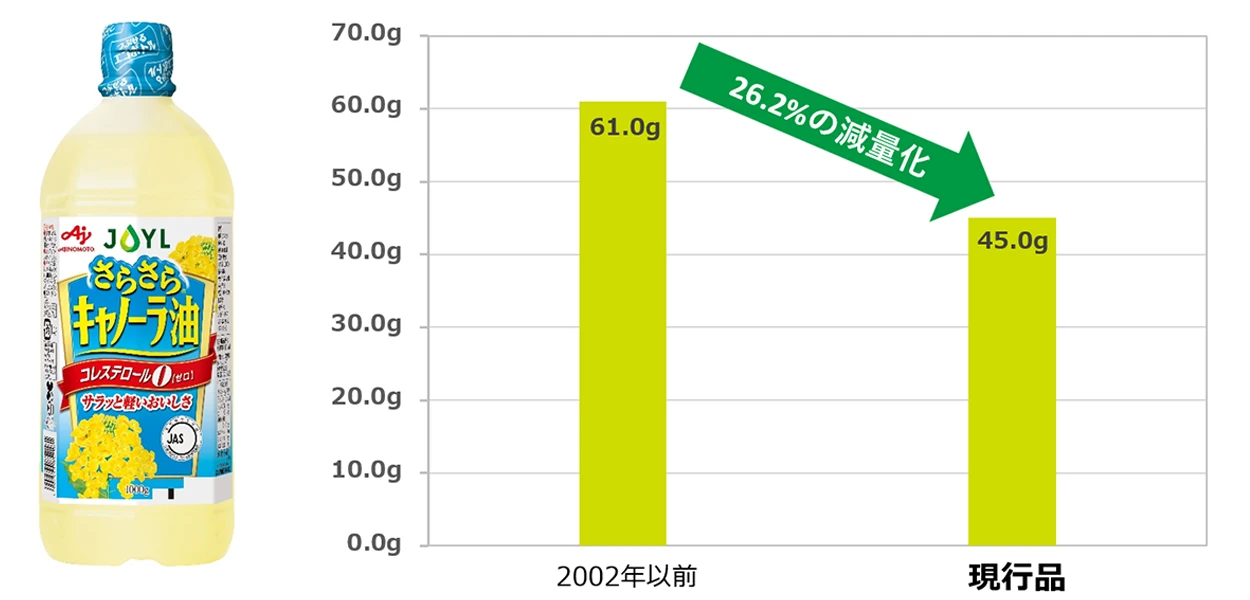

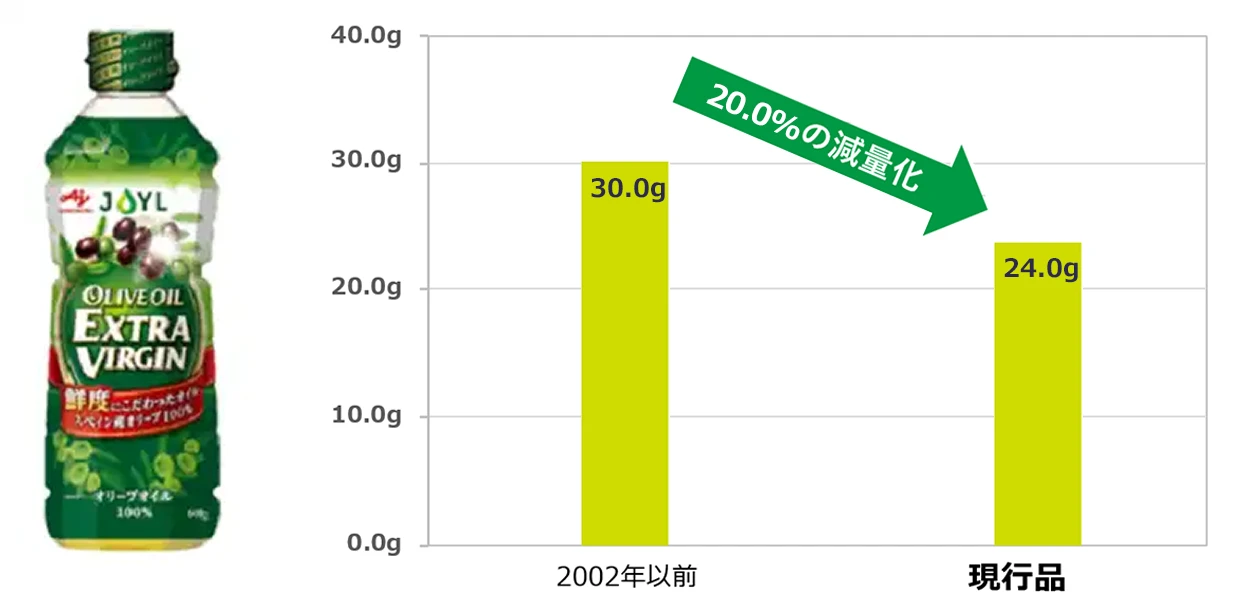

Efforts to reduce the weight of plastics

We have been actively working to reduce and lighten the amount of plastic used in our main packaging and containers for some time now. In collaboration with container and material manufacturers, we have promoted weight reduction efforts, and the weight of Eco Bottles (polyethylene bottles), which are used as containers for our main household oils and fats products, has been reduced by 26.2% compared to before 2002. In addition, the weight of UD Eco Pet (PET bottles), another main product container, has been reduced by 20.0% compared to before 2007.

1000g Eco Bottle Bottle Weight Trend

600gUD* Ecopet Pet weight trends

*Universal design

Initiatives to reduce plastic

"Smart Green Pack®"is an environmentally friendly product that uses paper packs

The "Smart Green Pack®" series is a series that pursues packaging functionality and environmental friendliness by using paper cartons, which are rare for oil and fat products, as containers in order to promote the reduction of plastic waste and CO2, which are our priority initiatives. After launching two products in August 2021, the series will be launched in spring 2022.

In July 2024 「

「![]() "Double Half"

"Double Half" 「

「![]() Cooking oil rich in rice bran oil

Cooking oil rich in rice bran oil 「

「![]() EurOlive®」(ユーロリーブ)」の3品を同シリーズから新たに発売しました。

EurOlive®」(ユーロリーブ)」の3品を同シリーズから新たに発売しました。

"Smart Green Pack®" series

*Related release: July 2, 2024

Oil that cuts usage and oil splashes in half *1 in a paper pack! JOYL "AJINOMOTO Double Half" Smart Green Pack® launched - Nationwide release starting August 20th (Tuesday) -

Recycled PET resin is used for the bottle and part of the label

In February 2024, we released a new product and renewed it, and we are now using recycled PET resin made from refurbished and recycled used PET bottles for some of the bottles and labels. We will continue to expand similar initiatives in the future.

Product design aimed at realizing "low-impact" value

We have formulated the "Environmental Guidelines for Realizing 'Low Burden' Value" with the aim of contributing to reducing the burden on society and the environment. Based on these guidelines, we operate a checklist to proactively incorporate our corporate philosophy of reducing the environmental burden from the product design and development stage. In fiscal 2023, we expanded the scope of operation from oil and fat products to non-oil and fat products, and ensured that evaluations using the environmental checklist were carried out when new products were launched. We will continue to work to create a sustainable society by consistently confirming the reduction of environmental burden from raw materials to manufacturing, transportation, consumption, and disposal.