Product Development

We aim to provide customers with high-quality products and services that increase value, and we continue to develop new products every day, never satisfied with the status quo.

AJINOMOTO Olive Oil Initiative

Improving quality throughout the value chain

Our flagship product, olive oil, is made up of products that we work on a daily basis to further improve value and peace of mind through a total approach to the value chain (from raw materials to the dining table).

For example, when it comes to upstream raw materials, we have a system in place where we purchase olive oil from our designated suppliers in advance to be able to provide our customers with higher quality products. Before purchasing, we check the quality from both the sensory perspective (flavor quality) and physicochemical analysis perspectives to ensure that the quality meets our company's standards.

In addition to the upstream process, we also work on the manufacturing side to prevent product quality from deteriorating before it reaches the customer, as well as on reducing volume and using new packaging materials to maintain quality in stores and at home. We carry out our development work with the aim of continuing to provide customers with even higher quality products.

Maintaining and improving quality evaluation levels

As part of our efforts to maintain and improve our own quality evaluation level, in terms of sensory aspects, we have been certified by the American Oil Chemists' Society (AOCS) "Olive Oil Sensory Evaluation Panel" for five consecutive years since August 2018. In terms of physicochemical analysis, we became the first Japanese company to obtain the International Olive Council (IOC) olive oil physicochemical type A certification in December 2018, and have continued to receive this certification in 2019 and 2020. In addition, we became the first Japanese company to obtain type B certification, a higher-level certification with more test items, in 2021, and have continued to receive this certification in 2022. We will continue to work hard to continue obtaining certification in the future.

Improved packaging to maintain freshness

This product has expanded its uses, such as "pouring" olive oil directly on food, and is used more frequently at the dinner table. In order to maintain the freshness of the oil even after opening, we have added a small, easy-to-use freshness-keeping bottle type product to the conventional bottle and PET bottle packaging. We aim to expand the range of container options available to customers and further stimulate the market.

Examples of initiatives for commercial oils and fats

Long-lasting oil

Our core technology, the SUSTEC® manufacturing process, makes use of the ingredients originally contained in the oil to produce an oil that lasts longer than regular frying oil.

By suppressing color, odor, and oxidation and prolonging the life of the oil, we can not only reduce the amount of raw materials (grains) used,

This will lead to the suppression of activities in all parts of the supply chain, from the collection of raw materials to transportation, storage, production processes, packaging materials, and product shipping.

This will reduce the amount of CO2 emitted from the oil, and also reduce the amount of oil that is disposed of after customers have used it.

We are able to provide total solutions that ensure the longevity of commercial oils through both the ingredients of the oil and how it is used.

seasoning oil

The Butter Flavor Oil series uses our unique technology to reproduce the aroma and richness of three types of butter. There are many types of butter on the market, each with a different flavor due to different manufacturing methods and origins, but we surveyed butter on the market to find the butter flavor that Japanese people really like. We then analyzed the flavor elements that make up the butter flavor and examined which elements are most important for a butter-like flavor, and found that butter with a "milky aroma and richness" is the key element. Using our unique technology, we succeeded in reproducing a milky aroma and rich flavor, and developed the Premier Butter Flavor Oil. In addition, we have different types to choose from depending on your menu or preference: a butter flavor oil that reproduces a strong top aroma and mellow richness, and a rich butter flavor oil that reproduces the rich aroma and richness of fermented butter.

Starch Initiatives

~Designing "texture"~

When coming up with new concepts in food development, expressions related to "texture" are increasingly being used, and they have become an essential component in designing deliciousness.

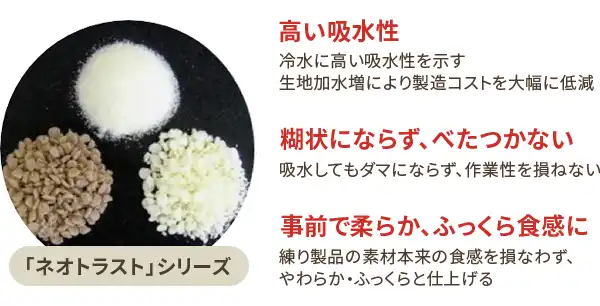

By processing carefully selected starch with our unique technology, we have developed "TXdeSIGN ®Neotrust®", which allows you to design a fluffy and melt-in-your-mouth "texture". Conventional water-retaining materials become sticky and pasty when they absorb water, but "TXdeSIGN ®Neotrust®"is a material that can create a natural fluffy and melt-in-your-mouth feeling while making use of the natural "texture" of the food.

It is used for a wide variety of purposes, mainly for processed meat products, sweets, and bread products.